Hello,

Now that temperatures have cool down a bit, we can all go back to modelling without fear of seeing the plastic melting on the workbench.

Last week, we told you about using a back to back gauge to check the wheels on your engines and rolling stock. We had not anticipated the interest and quickly ran out of the OO gauge. In case you missed it, it is now back in stock and the N gauge version as well. Click here for the full range including track gauges.

After years of modelling, we all have habits and are used to certain

things a certain way. However, there are usually tools that are now

available to make our life easier and safer.

On a similar token, when using flexible track, how do you cut the track? Most people use a hacksaw or a mini drill with a cutting disk. The issue is the fact the track is flexible, which means it moves. How do you hold the track in place, while cutting it? And if it moves the slightest, you know you will have to file and deburr the ends.

A track cutter solves the issue.

Simply use it like a pair of pliers: hold the track with one hand and

use the cutter using the other. You will get a clean cut with minimum

filing required, if any. This is safe, quick and efficient and

compatible with all small gauges (OO, HO, N, OO9, etc...). They exist in two types: one which cuts the track before being installed and the other cuts the track in place. As usual, click on the picture for full details.

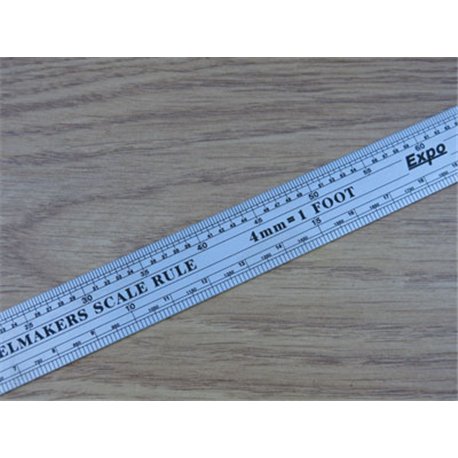

Most of us are scale modellers. We model to an exact scale: we measure the real thing, divide by a known number and get the measurements to use on the model. However sometimes, it is useful to simply be able to grab a piece of material or an existing model and measure directly in the real dimension: if you house wall would be 1.2 meter high, it means you made a mistake!

We stock a wide range of metal rulers designed to help scale measuring. They show you the size in centimeters

and millimeters as well as the "real life" size. Available in all usual

scales (OO, N, O, 1/35, 1/72, 1/87, 1/12 and 1/24), they will prove invaluable on a

day to day basis. The full range is available if you click here.

Precision is key. So why do we insist of using glue straight out of a tube? Even if the tube comes with a nozzle, usually the fact you have to press the container to push the glue out, rules out any detailed work.

The right approach is to use small syringes, filled with a small amount of glue. You can then use the tiny needle to put the glue where needed and push it out with minimum force. This set of syringes with 3 needles of various sizes will help get closer to perfection.

Finally, if you have a Hornby engine like the Terrier, you have probably experienced the issue of the rods unscrewing itself. This can happen over time and is a bit fiddly to put back as the hex screws are very small and difficult to hold with pliers.

This tool solves the problem: it is a screwdriver of the right size and shape, that is 2.5mm hexagonal and fits the screws perfectly.

Remember that most tools will last a lifetime, so they are a smart investment.

Send us an email or give us a call to check availability or to reserve anything, whatever scale you model in. As usual, if we do not have in stock what you are looking for, we will order it for you and you will get it fast (usually within a week if the manufacturer has it in stock). We place weekly orders with most suppliers.

Remember, you can park for free for one hour on the High Street. So no excuse not to come and visit us!

Upstairs Downstairs is open Tuesday to Saturday 10am till 4.30pm and Sunday 1pm till 4pm. We are closed only on Monday.

Steve, Carole & Max

--

Upstairs Downstairs

3 Pier Street

Sandown, PO36 8JR

Isle of Wight

Tel: 01983 406 616

http://www.trainshop.co.uk or find us on Facebook

Please forward this newsletter to your friends! They will thank you for it! Simply click here.

If for some reason you do not want to receive this newsletter anymore, click this link to unsubscribe.